Source: Solar Heat Europe

SHIP is the acronym for Solar Heat for Industrial Processes and describes systems which provide solar heat in a factory.

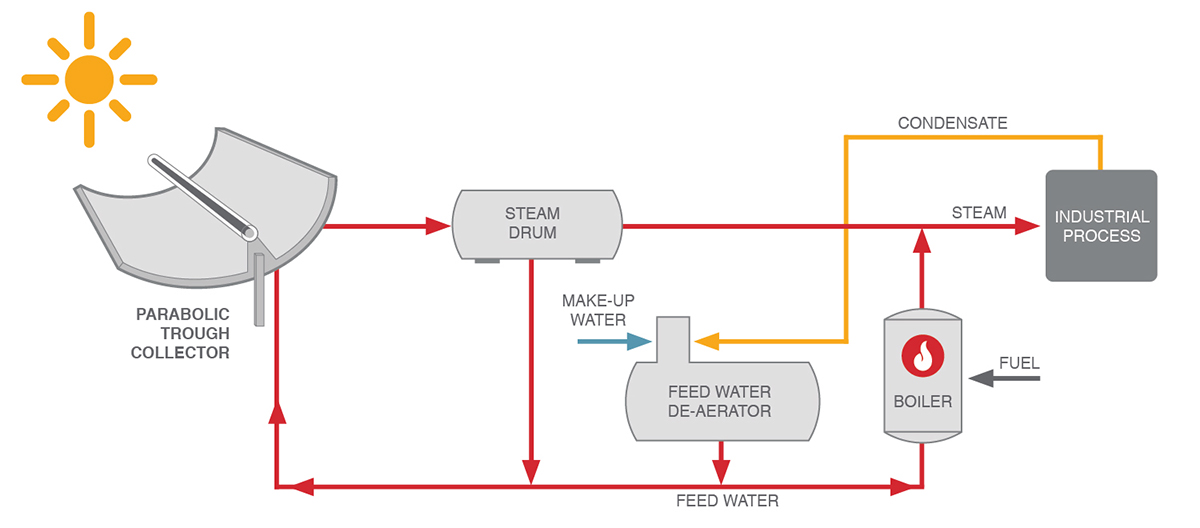

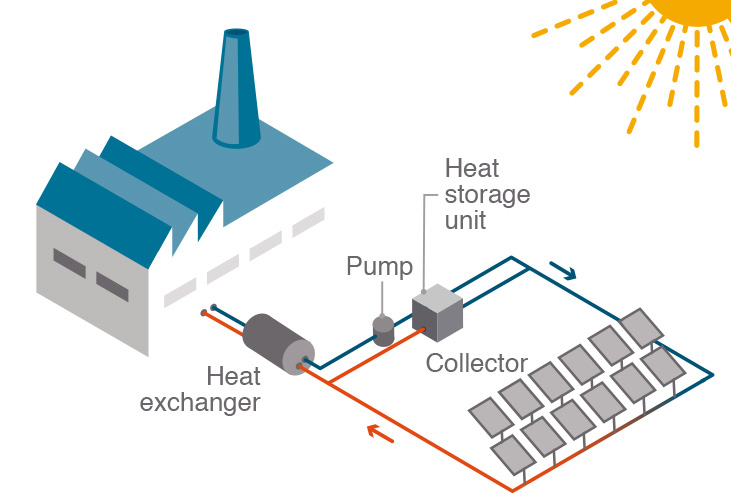

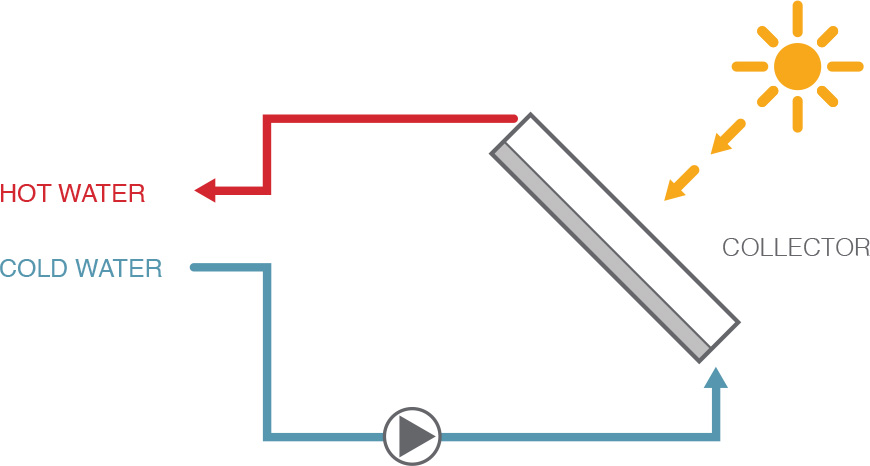

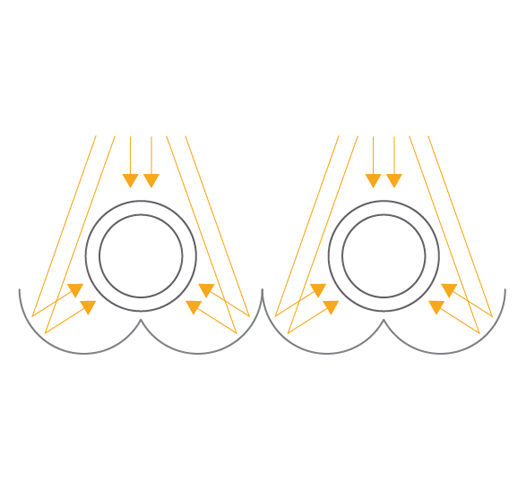

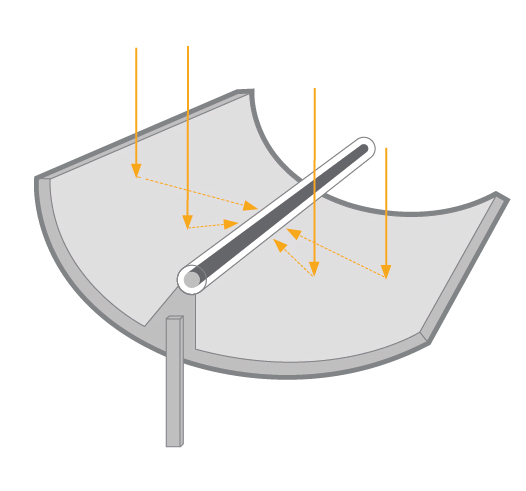

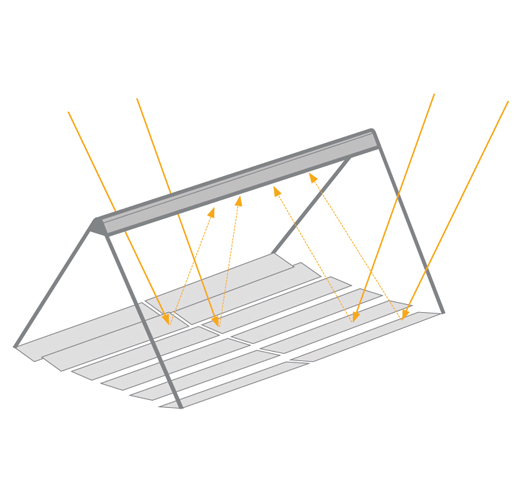

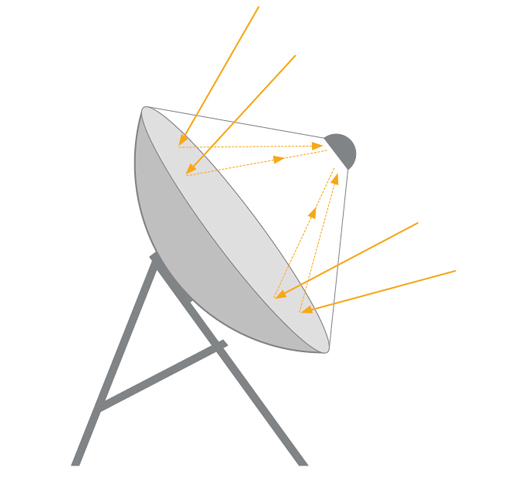

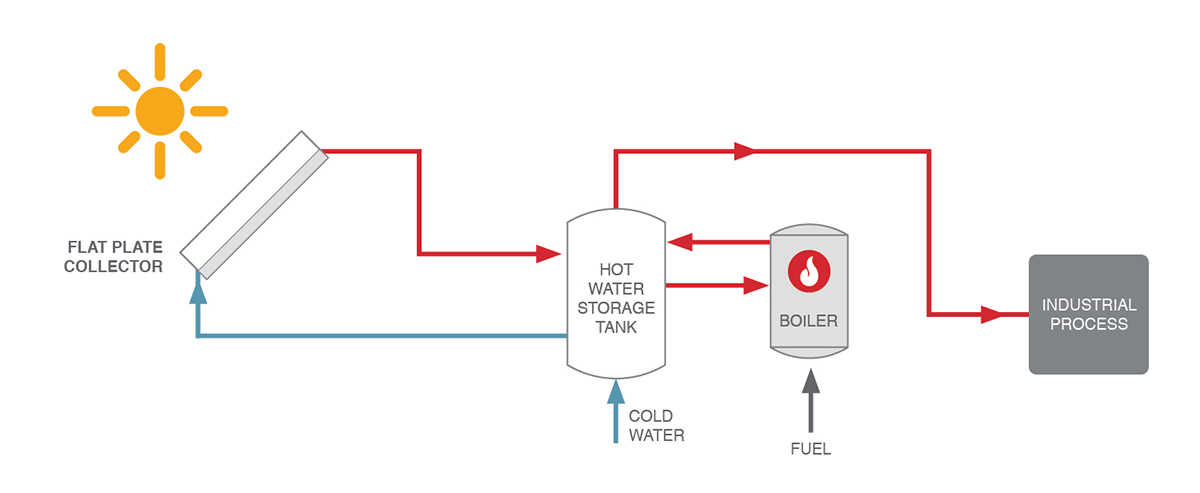

A collector field heats a process fluid by means of solar radiation and a heat exchanger transfers this heat to a supply system or production process in the factory as hot water, air flow or steam. Storage units make it possible to use the generated heat at night-time.

Source: IRENA

Source: IRENA